Why use Armoured Joints at all?

Construction joints are an essential part of creating a concrete floor. But left unprotected, they will quickly become damaged once the building is brought into use – leaving the building owner or operator with repair costs and expensive down-time. A damaged construction joint is more than just unsightly. Materials handling vehicles can suffer costly damage too on an uneven surface; and it can even present a health and safety issue for forklift drivers.

The best solution is to armour joint arrises during construction, to build in protection from the start. It is easy and cost-effective, and reaps benefits for the lifetime of the building.

How do Armoured Joints work?

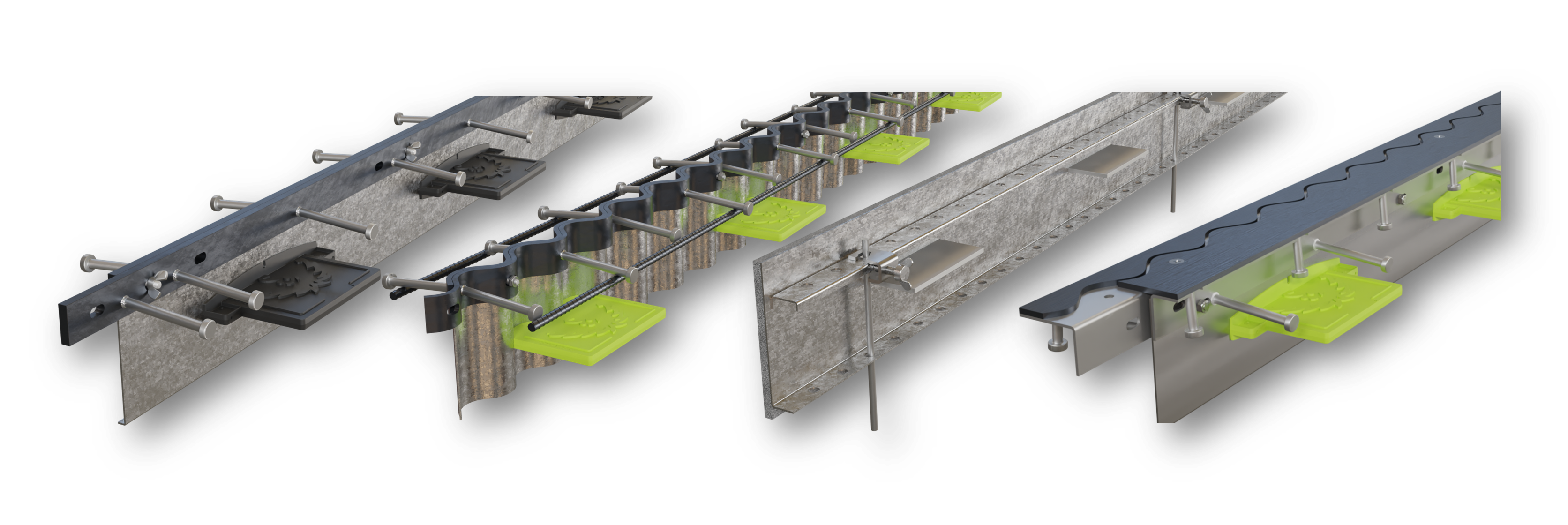

Armoured joints which also act as leave-in-place formwork are used to create a boundary in which to contain a day’s concrete pour. As the concrete sets and contracts, the two sides of the joint (held together with frangible connectors) are gradually pulled apart horizontally. Dowels fixed through the centre, stop the slabs moving vertically and allow for load transfer between the two sections of the floor. Once the floor has contracted, the gap between the two sides can simply be filled with a suitable joint sealant.

How do I know which Armoured Joint to use?

This will depend on several things, such as the type of building, how it will be used, and the type of vehicles that will pass over the joint. Often there will be more than one suitable option, and it may also be that more than one kind of armoured joint or formwork is needed for your project. We can help you find the best combination.

Guidance on choosing the right joint

Here are some of the factors to consider when choosing an armoured joint.

Building use. Consider whether the building will have one use in its lifetime, or if this may change. You can future-proof the floor by choosing a versatile joint, such as Wawe or Sinus Slide. These allow vehicles to cross the floor freely in any direction, now and in future.

Traffic. Consider the type of vehicle wheel being used, plus traffic frequency and speed (‘duty’). Vehicle direction determines how much impact a joint endures. Straight joints such as Terajoint are fine where vehicles won’t cross directly. Otherwise, choose a shaped joint such Wawe or Sinus Slide to prevent impact.

Service. If cleaning chemicals are regularly used, a stainless steel joint will withstand these and look good for longer. If a joint is used on external slabs and/or likely to be regularly exposed to wet conditions, choose a galvanised finish.

Hazards. If the building handles substances which must not leach into the ground, or where the joint gap itself would pose a hazard to pedestrians, then cover the gap permanently with Sinus or Parallel Slide Plate Joint, or fill with a joint sealant.

Floor construction. ‘Jointless’ floors include armoured joints, but not saw-cut joints, so the gap sizes can be slightly larger. Take the likely gap size into account, and how it might be filled. Sinus or Parallel Slide Plate Joint handles larger gaps and ensures no joint gap is exposed.

What height of Armoured Joint do I need?

This depends on the depth of the concrete slab being poured. Normally you would choose a joint size 10-30mm less than the depth of your slab – so if your nominal slab depth was 180mm you would use a 160mm high joint.

Why are the joint heights less than the slab depths?

Firstly, it's to allow for variances in the sub-base. The sub-base usually has a tolerance of +/- 1cm; so if the sub-base is created slightly out of tolerance, there is still space for the joint to move freely. The joint will not work if it is dug into the sub-base. Secondly, it gives a tolerance for levelling the surface.

What is impact?

If a vehicle crosses a straight joint at 90° there is a risk of impact damage. This is because the wheels drop momentarily in the gap between the two straight sides of the joint. Repeated impact on a saw-cut joint, or even a straight armoured joint, causes damage to the surrounding concrete, leading to maintenance costs and downtime.

A shaped joint arris (Wawe or Sinus Slide) has no straight lines–hence the wheels cannot fall between the two sides, so no impact can occur. Shaped joints therefore make the ideal choice for directional traffic situations, or where a building owner wants to ensure flexibility for how a building may be used in the future.

The value-engineered approach

Traditional-style armoured joints only account for about 5% of the material cost of the floor slab. Joints are a small part of the overall cost –but can make an enormous difference to the floor’s lifetime performance.

By using a combination of armoured joints you can create an optimum specification without a significant cost increase. For example, using straight and shaped together in a specification will provide superior joint protection, but with a less than 1% increase in material cost. Using shaped (Wawe) alone means only a 3% increase in material cost. But remember that any additional up-front costs will be more than recouped over the life of the building, due to reduced floor and vehicle maintenance costs. The building’s versatility, and saleability, can also be improved.